Products

Thermy

Temperature defines the world we live and work in — but it’s invisible. Thermy lets your business remotely manage for temperature.

Whether it’s ensuring meat and produce remain at safe temperatures, or checking that staff and civilians don’t pose a health risk to your operation, Bigmate’s Thermy is the ideal complement to your operations.

Thermy takes your key temperature scenarios and objectives and, using CCTV cameras outfitted with AI and Machine Learning algorithms, turns them into actionable alerts and workflows.

Industries

-

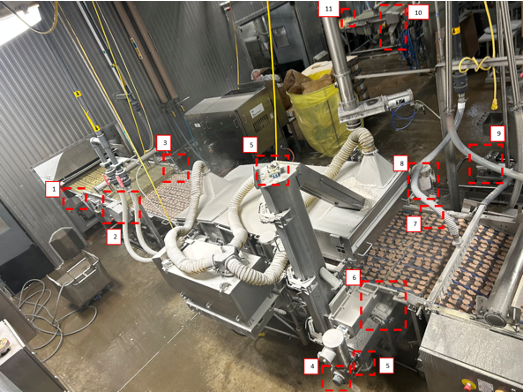

Food Processing

Thermy helps complex food processing plants ensure their products are going through the correct temperature cycles during processing to optimise quality and reduce contamination risk.

-

Resources

Processing minerals and resources can involve extreme temperature modulation processes. Thermy allows operations to monitor for optimal consistency.

-

Manufacturing & Logistics

Thermy allows operations staff to ensure illness and operating risks such as fires and stoppages can be remotely identified before they spread and disrupt incredibly energy intensive operations.

What Thermy Is Used For

Core temperature assessment

Thermy™ allows businesses to evaluate the core temperature of staff and guests and compare them to expected acceptable levels for the area of the facility they’re active in.

Live body temperature assessment and flagging for abnormalities

Accurate within +/- 0.35 degrees Farenheit/0.15 degrees Celcius

Securely hosted on AWS

No facial recognition, so testing is anonymous

Can be applied to existing security camera implementations or new set ups.

State changes in products

Thermy™ allows operations that put products through temperature change processes to reach the necessary state for the next stage of processing — for example cooking or freezing — confident that the product has been appropriately transformed.

AI-driven alerting, decisioning and reporting based on documented business rules

Start & end of process core temperature measurement

Moisture-change measurement

Latest in hyperspectral image analysis technology

Predictive maintenance

Plant and equipment are often forced to work long hours performing repetitive tasks. Over the course of their serviceable life, maintenance requirements can come out of the blue well ahead of any planned shutdowns/maintenance windows.

Thermy can be used to take baseline conditions for a piece of plant or equipment and then monitor for variations against the baseline, meaning your operations team can be alerted when any identified component exhibits heat signatures outside of the expected and/or acceptable ranges.